About Shrink Packaging

Shrink Wrapping, Shrink Packaging, or Bundle Wrapping is a packaging process in where a group of products are wrapped in shrinkable plastic film which, after exposing them to hot air, holds the products firmly together for transport as either a sales unit or for ease of inventory management.

Advantages of shrink wrapping

-

Cost-effective, water-resistant, and causes less scuffing of labels.

-

Easier and much cheaper to automate in comparison to tray or case packing.

-

The product can be seen through the film (unlike cardboard)

-

Leaking is mostly contained to single packs, which prevents damage to full pallets.

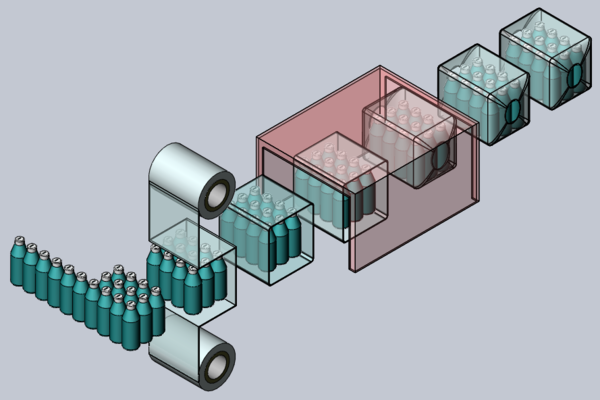

The shrink wrapping process

Like any packaging process, shrink packaging involves preparation of wrapping material (film), preparation of products, enclosing (wrapping) in a sleeve of LDPE film, then shrinking / cooling and discharge.

The shrink wrapping process consists of 3 main steps:

Product grouping

- The products are arranged into a group (e.g. 3×2 bottles to form a 6-pack). In slower machines, the product is fed in a single lane and grouped inside the machine by successive strokes of pneumatic or electric pushers (or lifters). In faster machines, the product is introduced in multi lanes or pre-collated outside of the machine.

Bundle forming

-

A sheet of shrink film is wrapped around the products, forming a bundle. There are currently two main ways of wrapping the product:

-

Using two rolls with hot knife cutting and sealing

-

Using single roll with cold knife cutting and overlap sealing in the tunnel

-

Heat shrinking

The bundle passes through a heated zone of the shrink tunnel, where re-circulated hot air causes the film to shrink and conform to the shape of the enclosed products. Once outside, the pack is cooled by forced air to tighten the film; this creates a semi-rigid pack that's ready for stacking on pallets or to be moved further down the packaging line.

Weld Bar Sealing vs Overlap Sealing

There are two ways of wrapping the shrink film around the products.

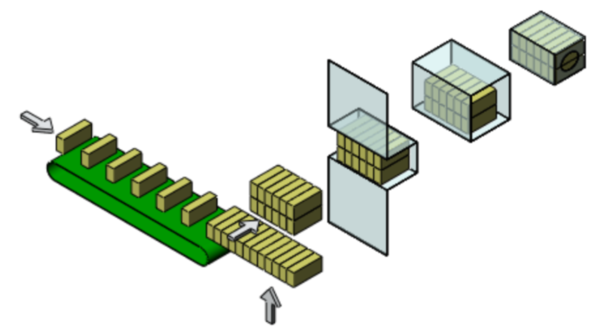

Weld Bar Sealing

- This is the traditional way of Sleeve Wrapping: two top and bottom film rolls are joined to form a film curtain. When the product is ready, it is pushed through. The Welding Bar (Sealing Bar) then comes down to form a sleeve on the collation of product simultaneously, cutting the film and rejoining the curtain for the subsequent pack.

Overlap Seal

- This process uses a single film roll: a pre-cut sheet of film is wrapped around the product with the loose ends overlapping beneath the pack. The overlapped region is partially fused in the shrink tunnel while the rest of the sleeve is shrunk to enclose the contents.

- The main advantage of Weld Bar type machines is lower cost and smaller footprint.

- The main advantage of overlap machines is that they produce higher throughput.

Shrinkwrapping FAQ

What sorts of products can be shrink-wrapped?

Most bottles, cans, cartons, and boxes are ideal for shrink wrapping. It is also possible to shrink wrap many other sorts of products. If you're not sure if your product would lend itself well to shrink wrapping, then give us a call--we'll have the answer.

Can the high temperature of the shrink process affect my products?

Due to the short exposure time and protection offered by the shrink film itself, very few products are affected by the process. Even foil-wrapped chocolate can be shrink-wrapped. However thin PVC trays, thin PET containers, or not fully filled CSD bottles can distort during the shrinking process.

How many products can fit in a bundle?

It depends on the size and weight of the products. 12 drink cans (4×3) can be securely wrapped. With smaller products, more can be included. Note that we have vertical stacking options to allow multiple layers of cans and boxes

Are the products fully enclosed?

No. Although the film shrinks around the products, there will be a round opening in the film on either side of the pack, called "bulls eyes".

Can I use the same machine for different products?

Certainly!. Most Autopack machines are designed to be rapidly adjustable to a wide range of products. Contact us if you would like to find the best machine to suit your needs.

Pads and trays

For additional pack strength or ease of handling, a cardboard pad or tray can be introduced under the product before being shrink-wrapped.

Alternatives to shrink wrapping

All these forms of packaging can have custom designs printed on the packaging.

Cardboard cartons/boxes

One or more products are fully enclosed. The box can be sealed with glue/tape, or with interlocking flaps (like toothpaste cartons).

Cardboard trays

The products are placed in a cardboard tray for easier handling.

Cardboard/plastic crates

Similar to trays; however, crates are more durable and reusable.